Hands-On Experience

13 years of designing boat canopies, covers, and upholstered products has given deep expertise in taking concepts from initial idea to production-ready designs – working fluently with both traditional hands-on methods and modern digital workflows, choosing the right approach for each project.

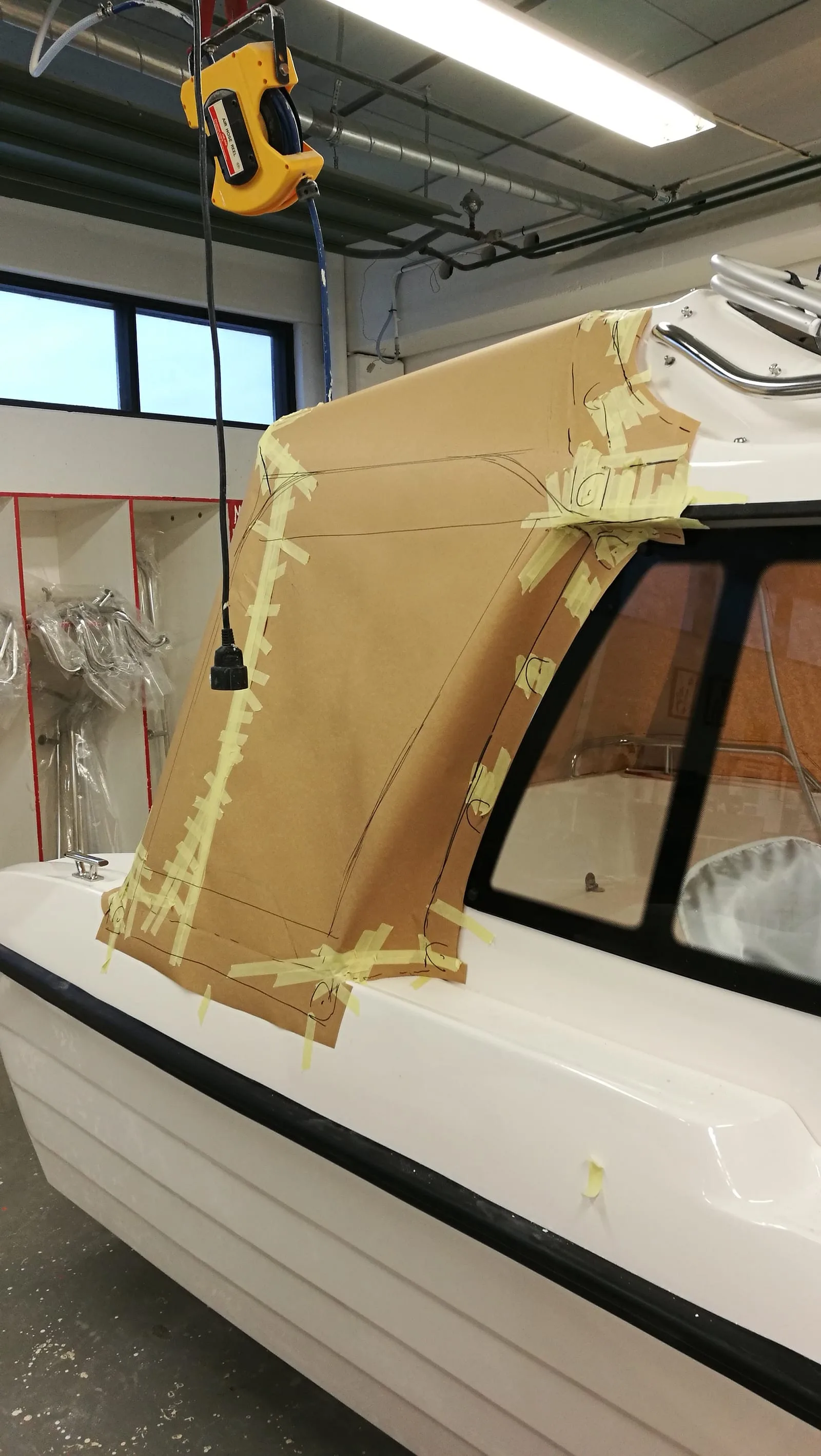

Traditional Pattern Development

Extensive experience creating various types of 1:1 scale patterns: full boat canopy models, protective covers, and upholstery products like seat upholstery and cushions. Using paper and plastic sheeting directly on boats, shaping the material around complex hull geometries, marking seams and attachment points, then flattening the 3D form into 2D pattern pieces. These patterns are transferred to CAD for CNC cutting or – when speed is critical – cut manually with scissors straight into production.

Digital Design Pipeline

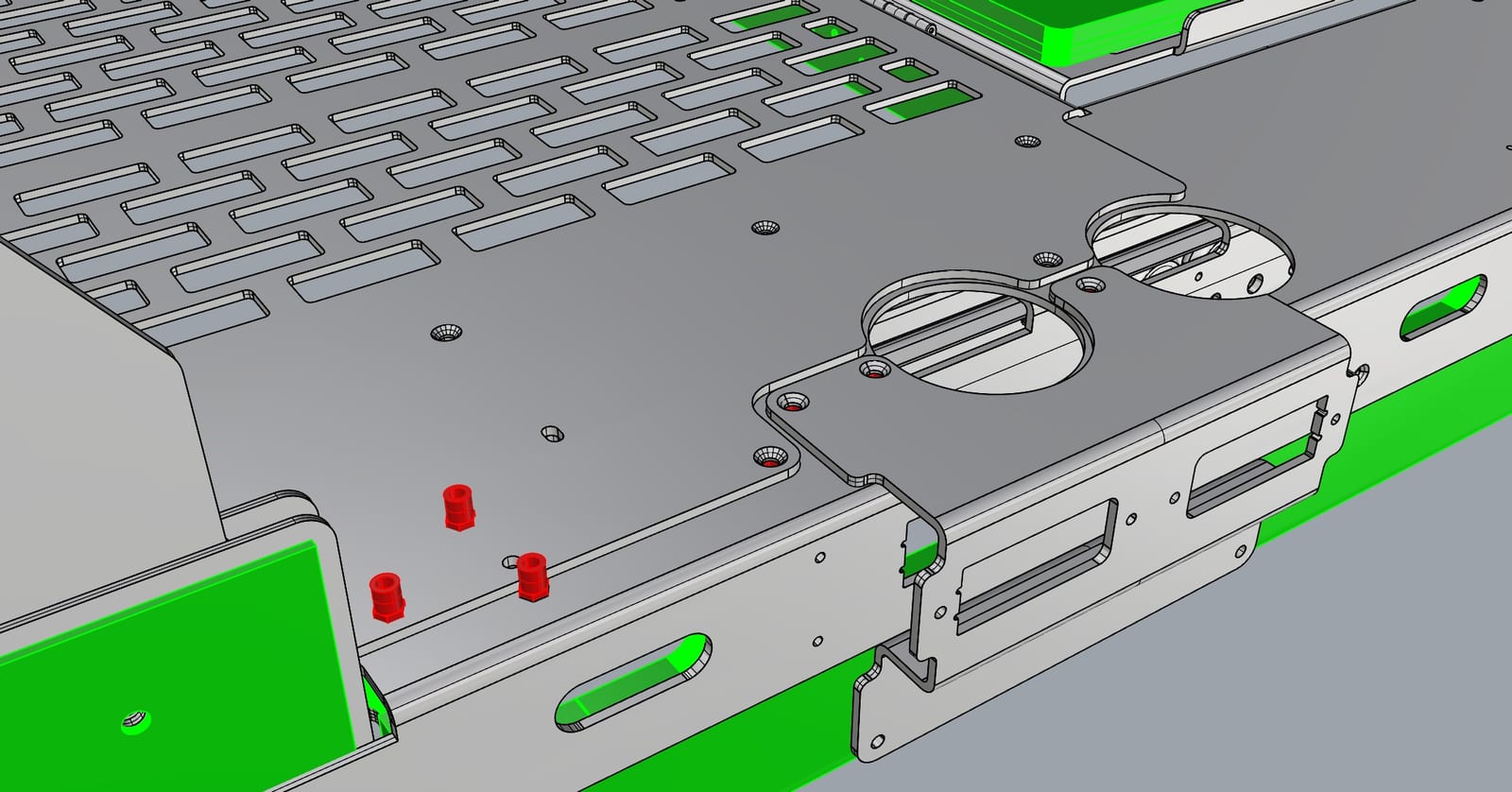

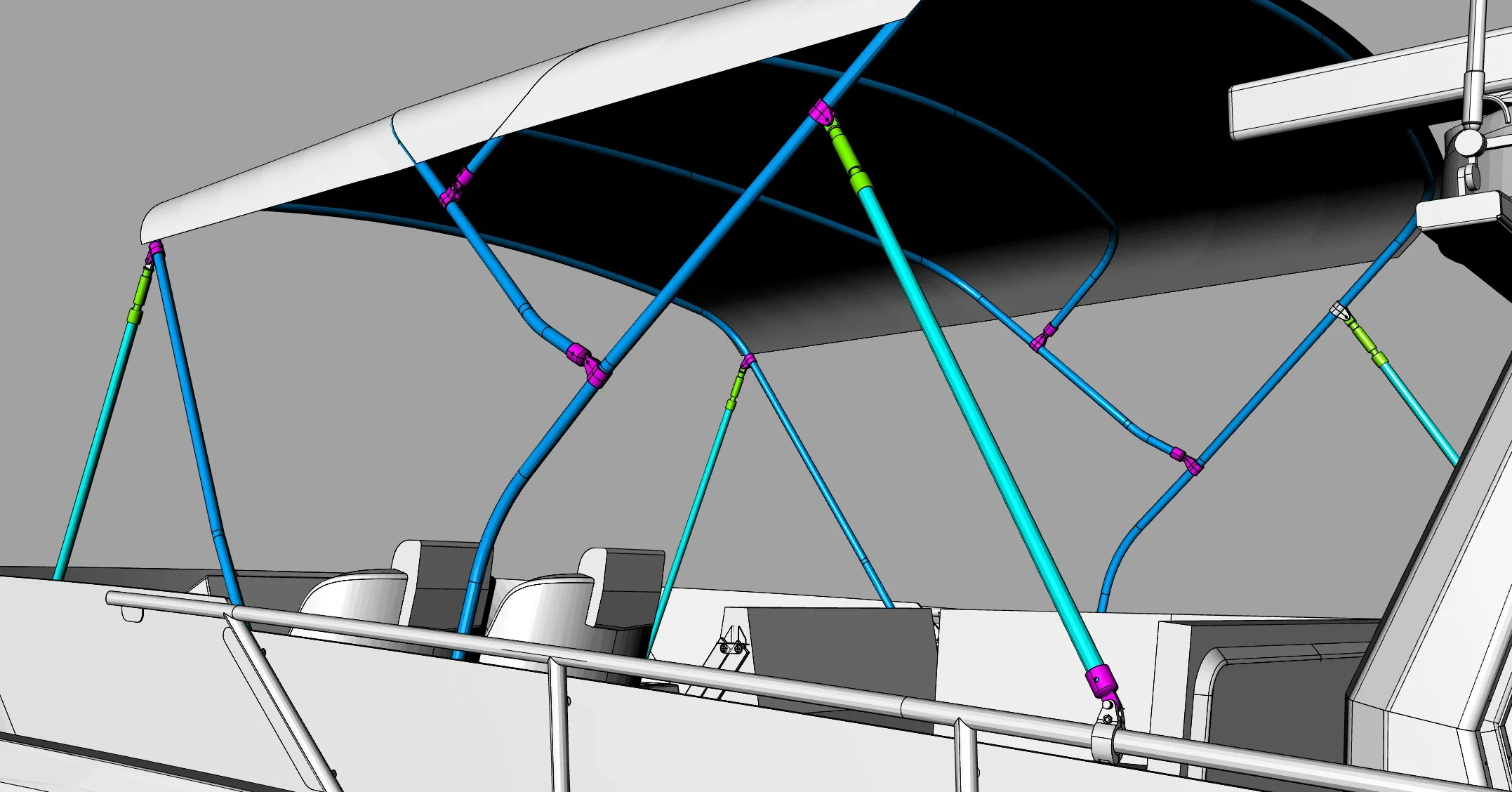

Working with client-provided 3D boat models or performing on-site 3D scanning. Designing canvas surfaces, enclosure systems, and canopy pipe frames in 3D software, then converting the designs to 2D production patterns and technical production drawings – including complete working drawings for canopy frames used in pipe bending. Full documentation included: manufacturing instructions and customer installation manuals.

For cushions and upholstery products, this extends to foam, plastic, plywood, and metal cutting drawings for subcontractors.

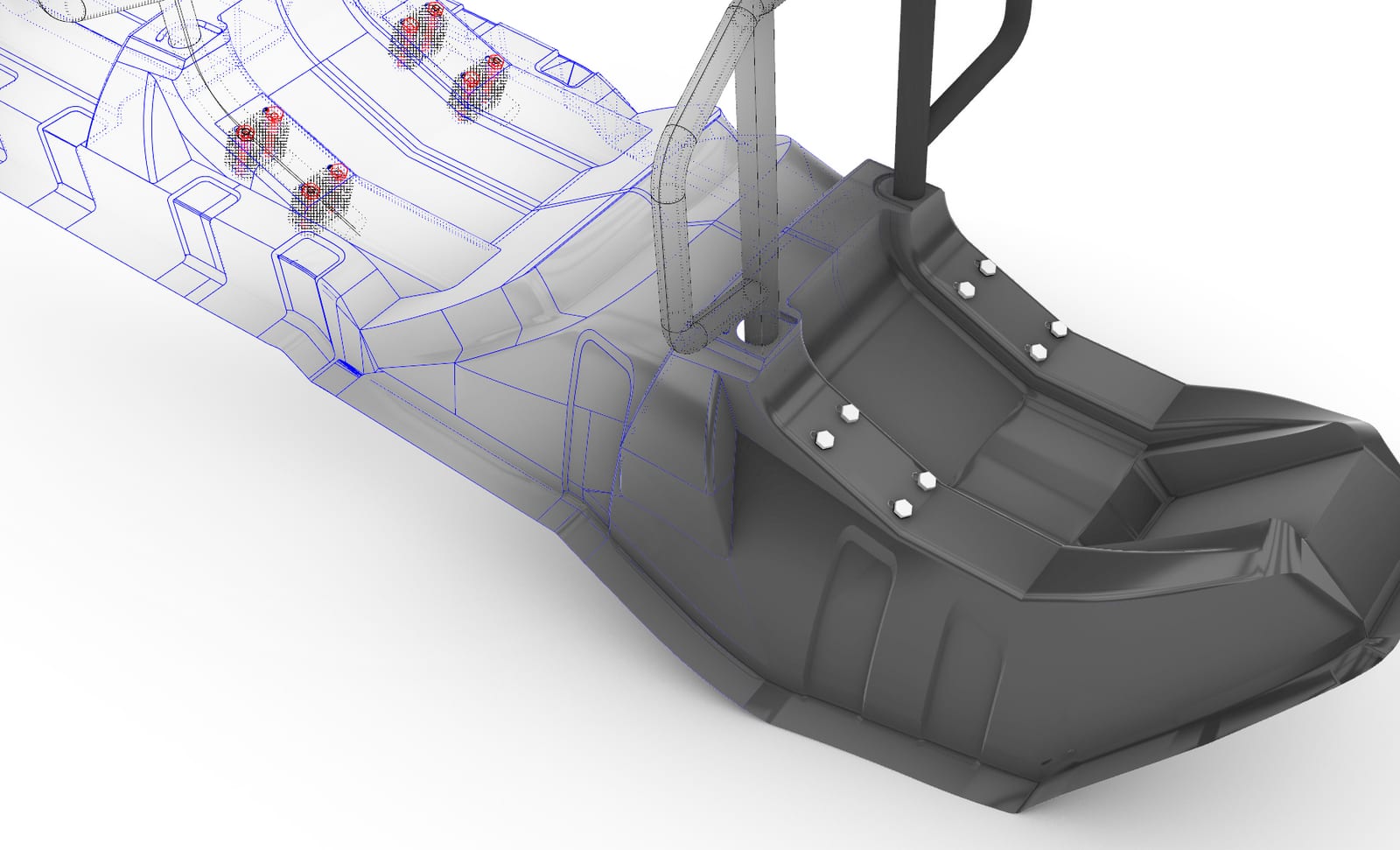

Prototype Building

Hands-on prototype development for cushions and upholstery solutions. Creating component drawings, sourcing parts, and when needed – manufacturing them manually. Shaping foam on a bandsaw, building structural frames, and assembling complete prototypes combining wood, metal, plastic, foam, and upholstery into functional, production-ready designs.

Early-stage simple prototype test structures help evaluate functionality and dimensions before committing to full production. Multi-material mockup models solve problems early, reducing costly revisions during actual prototype manufacturing.

Frame & Structure Design

Canopy systems require more than just canvas – functional geometry is essential. Pipe frames must often fold into storage compartments, requiring careful definition of movement paths that achieve both compact storage position and desired canopy shape when deployed. Fabric tension, frame geometry, and mounting points work together to create results that can be reliably manufactured and installed.

Upholstery and seating systems demand structural strength, secure mounting solutions, and reliable mechanisms. Foldable backrests, reversible cushions, position locks, and load-bearing frames – designed with metal, plastic, or plywood construction. Balancing aesthetics, functionality, durability, and manufacturability for serial production.